Electric knife sharpeners are devices designed for mechanically restoring the sharpness of blades in professional kitchens. They use electric motors that drive grinding wheels or sharpening stones of specific grit, restoring the proper sharpening angle of the blade. In professional gastronomy, they replace time-consuming manual sharpening, ensuring consistent results regardless of the operator’s skills.

Electric sharpening systems operate on the principle of a two-stage process: pre-shaping the blade using a coarser grit (220–400), followed by finishing and polishing with finer abrasives (800–1200). The guiding mechanism maintains a constant sharpening angle of 15–20° for European knives or 12–15° for Asian knives, eliminating the risk of blade damage due to incorrect positioning.

We distinguish 3 main categories of electric sharpeners in our offer:

- Two-stage sharpeners with guides – equipped with fixed-angle slots and ceramic or diamond stones. Power 50–120W, dedicated for steel knives 10–25 cm long. Rotational speed 1400–3000 rpm.

- Multi-stage sharpeners with adjustable angle – allow sharpening angle adjustment 12–25°, equipped with replaceable grinding discs of various grit. Power 150–250W, support knives up to 30 cm long. Additional water or air cooling system.

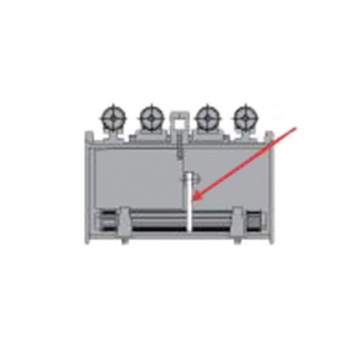

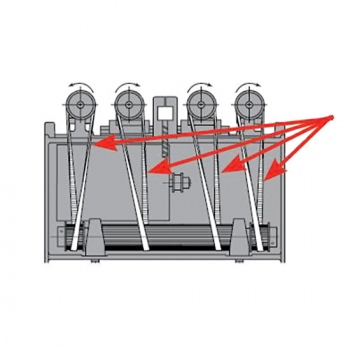

- Industrial sharpeners with guiding system – constructions with power 300–500W and precise blade positioning mechanisms. Equipped with speed regulators, metal chip removal systems, and the ability to sharpen specialized tools. Dedicated for intensive use in large kitchens.

Technical specifications and operating parameters

The basic technical parameters of electric sharpeners include motor power expressed in watts, which determines the ability to process harder steels. Devices with power of 50–80W are intended for soft stainless steel knives, while units of 150W+ handle carbon steels and ceramic composites.

Rotational speed of the discs controls processing aggressiveness – lower values of 1400–2000 rpm minimize blade overheating, higher 2500–3500 rpm speed up the process with the risk of steel temper loss. Abrasive grit defines the processing phase: 220–400 for repairing damaged blades, 600–800 for regular maintenance, 1000+ for finishing and polishing.

Professional models are equipped with temperature stabilization systems – air or water cooling prevents blade overheating above 65°C, which could cause loss of steel hardness. Guiding mechanisms made of aluminum or steel alloys ensure repeatable sharpening angle with a tolerance of ±1°.

The working dimensions of sharpeners are adapted to standard kitchen knives: minimum blade length 8–10 cm, maximum 25–35 cm depending on the model. Blade thickness should not exceed 3–4 mm in most household devices, while industrial models support blades up to 6 mm.

When choosing an electric sharpener, it is crucial to match device power to usage intensity – restaurants serving more than 100 customers daily require models with at least 150W power and a cooling system. Abrasive quality directly affects sharpening durability – ceramic abrasives provide uniform grinding, diamond ones offer the longest lifespan at the highest purchase price.