Knife sharpeners represent a fundamental category of devices used to restore and maintain the cutting performance of kitchen, butchery, and foodservice blades. In professional culinary environments, where cutting quality directly impacts workflow efficiency and the quality of prepared dishes, sharpening systems are an essential component of technical equipment. The sharpening process involves precisely removing microscopic damage from the cutting edge and restoring the proper sharpening angle, which for most kitchen knives is 15-20 degrees per side.

Modern sharpening technologies rely on a controlled abrasion process, where an abrasive material of a specific grit size (expressed in FEPA or JIS standards) gradually shapes a new edge geometry. The grit progression — from coarse (200-400 grit), through medium (800-1200 grit), to very fine (3000-8000 grit) — allows for a step-by-step transition from repairing damaged blades to final polishing of the cutting edge.

Our product range includes 4 main categories of knife sharpeners:

1. Manual sharpeners — precision of manual sharpening

Manual sharpeners represent a classic approach to maintaining knife sharpness, offering full control over the sharpening process. Traditional manual sharpeners are equipped with slot systems of varying abrasive grit — typically coarse (pre-sharpening), medium (sharpening), and fine (polishing). The guide construction ensures a consistent sharpening angle, eliminating the risk of damaging the blade geometry through improper handling.

Pocket sharpeners are compact solutions designed for mobile applications. Despite their small size, they retain the functionality of full-sized systems, offering basic grit stages necessary for quick edge restoration in field conditions.

2. Electric sharpeners — automation of the sharpening process

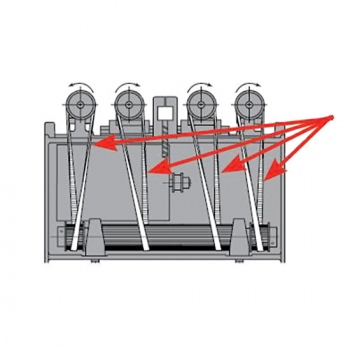

Electric knife sharpeners use an electric drive to rotate abrasive wheels, providing even and controlled sharpening action. Automatic sharpening systems feature precision guides that maintain the optimal angle of blade contact with the abrasive surface. Advanced models offer adjustable rotational speeds (typically 1500-3000 rpm) and various types of wheels — from aluminum oxide to synthetic diamond.

Multi-functional electric sharpeners expand the application scope to sharpening scissors, chisels, and other cutting tools. They are equipped with interchangeable guides adapted to different tool types, making them a versatile solution for foodservice establishments.

3. Sharpening stones — traditional precision of Japanese sharpening techniques

Water stones (whetstones) represent the oldest and most precise method of sharpening knives. They require soaking in water before use (soaking time: 5-15 minutes depending on porosity), ensuring the proper consistency of the abrasive slurry. Available grits range from 200 grit (restoring damaged blades) to 10000 grit (mirror polishing).

Diamond stones use microcrystals of diamond embedded in a metal or resin matrix. They are characterized by exceptional durability and do not require water soaking. Their effectiveness in sharpening hard steels (above 60 HRC) makes them the preferred choice for high-carbon and stainless steel knives.

4. Honing rods — daily maintenance of the cutting edge

Steel honing rods made of hardened steel (62-65 HRC) are used for daily straightening of microscopic bends in the knife edge. This process, called alignment, does not remove material but restores the blade’s original geometry.

Ceramic honing rods made of aluminum oxide or zirconium offer a gentler impact on the blade while maintaining effective performance. The hardness of ceramics (9 on the Mohs scale) ensures long-lasting abrasive properties.

Diamond honing rods combine the benefits of a steel core with a diamond coating, enabling effective sharpening even of heavily dulled blades. The coating grit (typically 600-1200 grit) allows precise control over the sharpening intensity.

Technical specifications and key parameters

Choosing the right sharpening system requires consideration of several key technical parameters. Abrasive grit determines the application — low values (200-600 grit) are used for restoring damaged blades, medium (800-1500 grit) for standard sharpening, and high (2000+ grit) for polishing and finishing.

Sharpening angle is a critical parameter affecting the knife’s cutting properties. European kitchen knives are sharpened at an angle of 20-22 degrees per side, Japanese knives at 15-17 degrees, and specialized sashimi knives even at 12 degrees. Precise angle maintenance is possible through the use of angle guides or guide systems.

Abrasive material affects the efficiency and durability of the sharpening process. Aluminum oxide (Al₂O₃) provides versatile use and good value for money. Silicon carbide (SiC) is harder and suitable for sharpening hardened steels. Synthetic diamond offers the highest efficiency for sharpening super-hard ceramic and composite steels.

Selection criteria and industry applications

In the foodservice environment, the choice of knife sharpener is driven by specific operational requirements. Fast-food restaurants prefer electric systems that offer speed and consistent sharpening quality. Fine-dining kitchens require precise water stones to achieve perfect sharpness for filleting and decorative cutting.

Butcher shops and meat processing plants use high-performance systems adapted to sharpening thick and heavy blades. The hardness gradient (from 400 to 1200 grit) enables a full tool restoration cycle within a single device.

Sharpening frequency depends on usage intensity — restaurant knives require daily alignment with a honing rod and weekly sharpening on a stone or sharpener. Professional sharpening systems should provide blade life of 200-500 sharpening cycles before requiring geometry restoration by a specialist.

Workplace safety and compliance with standards

Knife sharpening devices for foodservice must comply with the EN 12442 standard for food industry machine safety. Electric sharpeners require protection against water penetration (minimum IP44 rating) and must be equipped with a safety switch that stops operation when covers are opened.

Work ergonomics include a stable construction that eliminates vibration, appropriate working height, and an effective dust extraction system. Professional sharpening stations are equipped with aspiration systems and work lighting of at least 500 lux.

Regular maintenance of sharpening systems includes cleaning abrasive surfaces, checking guide geometry, and replacing consumable components according to the manufacturer’s schedule. Water stones require periodic flattening (diamond plate dressing) to maintain a flat working surface.

Technology trends and innovations

Modern sharpening systems integrate digital technologies that enable programming of sharpening parameters for different types of knives. Angle and pressure sensors ensure consistent results regardless of operator skill.

Hybrid systems combining various sharpening methods — diamonds, ceramics, and natural stones — allow comprehensive handling of the full spectrum of cutting tools within a single device. Automatic grit changes and intelligent water dosing systems represent the direction of development for industrial sharpening systems.

Innovative nanocrystalline coatings on abrasive surfaces extend the lifespan of sharpening tools while improving the quality of the sharpened surface. Laser surface profiling allows precise control of abrasive characteristics.

Choosing the right knife sharpening system is a strategic investment decision that impacts operational efficiency and the quality of final products in professional foodservice. A comprehensive approach that considers the specifics of application, safety requirements, and future technological trends ensures optimal return on investment and long-term operational reliability.