Water squeegees are specialized tools designed for the efficient removal of liquids from horizontal surfaces in foodservice facilities. Their construction is based on a flexible working rubber mounted in a metal or plastic holder, which enables precise directing of the collected water towards drains or collection points. In professional gastronomy, where HACCP standards require dry working surfaces, squeegees are a key element of sanitary equipment.

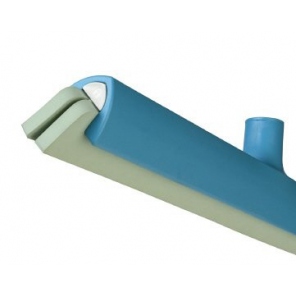

The operating mechanism of squeegees is based on the use of a scraping edge made of an elastomer with the proper hardness, which adapts to micro-irregularities of the surface, ensuring effective removal even of thin liquid layers. Differences in the elastic modulus of the rubber determine their application on specific types of flooring – from delicate ceramic tiles to industrial epoxy coatings.

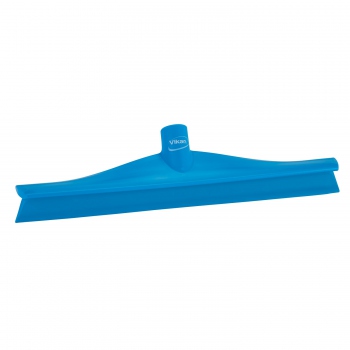

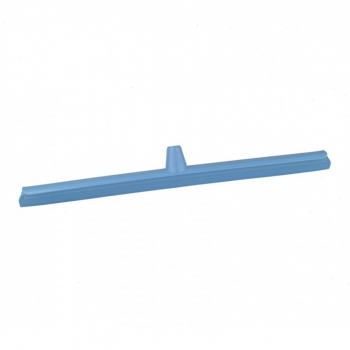

In our offer, we distinguish 4 main categories of water squeegees:

- Squeegees with replaceable rubber inserts – models with a quick-change system for the working element, extending the tool’s overall service life

- Squeegees with ergonomic handles – designs with contoured grips reducing wrist strain during long-term use

- Squeegees for telescopic poles – mounting heads compatible with standard handles with universal threads

- Complete sets – combination of squeegee and dedicated pole, providing optimal functionality and ergonomics

Technical specification and design parameters

Working widths of squeegees range from 35 cm for areas with limited accessibility to 75 cm for large production zones. Working rubber thickness is typically 4–6 mm, ensuring proper stiffness while maintaining flexibility. The materials used are usually nitrile-butadiene rubber (NBR) or thermoplastic polyurethane (TPU) with a hardness of 65–85 Shore A, resistant to food oils and cleaning agents.

Mounting holders are made of stainless steel AISI 304 or AISI 316L for environments with increased chemical aggressiveness. Screw connections are equipped with O-ring seals to prevent moisture penetration into the structure. Quick-change systems are based on clamping or threaded mechanisms compatible with Euro-standard holders.

Selecting the right squeegee requires considering the coefficient of friction between the rubber and the surface, attack angle optimal for the specific surface type, and the frequency of use. For anti-slip floors, rubbers with increased flexibility are recommended, while smooth surfaces require stiffer materials ensuring precise wiping without streaks.